cost of distribution transformer

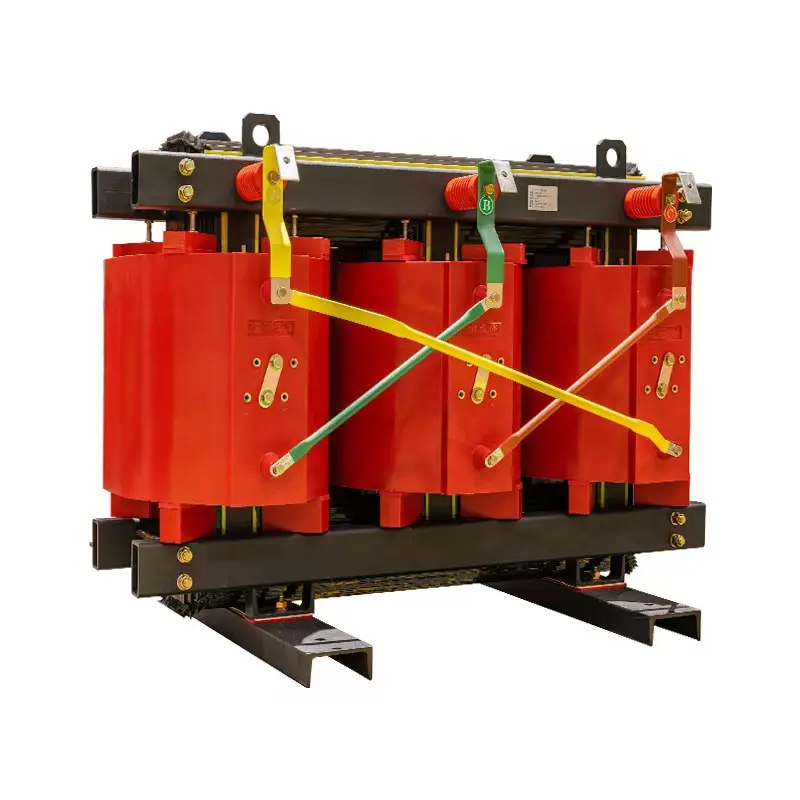

The cost of distribution transformers represents a crucial investment consideration in power distribution systems. These essential devices, which convert high-voltage electricity to lower voltages suitable for end-user consumption, vary significantly in price depending on several factors. Typically, distribution transformer costs range from $2,000 to $30,000, with factors such as power rating, efficiency class, cooling type, and installation requirements influencing the final price. The initial purchase price includes the core unit, insulation systems, protective components, and basic monitoring equipment. Modern distribution transformers incorporate advanced features like smart monitoring capabilities, enhanced energy efficiency ratings, and improved insulation materials, which can affect the overall cost. Installation costs typically add 20-30% to the base unit price, covering labor, site preparation, and necessary accessories. Maintenance costs over the transformer's lifetime must also be considered, generally averaging 1-2% of the initial cost annually. The total cost of ownership extends beyond the purchase price to include operational efficiency, maintenance requirements, and expected lifespan, typically 20-30 years. Understanding these cost components is essential for utilities, industrial facilities, and commercial buildings to make informed investment decisions that balance initial costs with long-term operational benefits.